- Introduction to laser cleaning technology

- Advantages of laser cleaning over traditional cleaning methods

- Comparison of different laser cleaning systems for ceramics

- Laser parameters optimization for efficient cleaning of ceramics

- Comparison of laser cleaning with other surface treatment methods for ceramics

- Laser cleaning for removing rust and corrosion from ceramics

- Laser cleaning for removing grease and oil from ceramics

- Laser cleaning for removing stains from ceramics

Introduction to laser cleaning technology

Introduction to laser cleaning technology

Laser cleaning technology is a cutting-edge method used to remove contaminants, coatings, rust, and other unwanted materials from surfaces. This innovative technique utilizes the power of laser beams to vaporize or ablate the surface layer, leaving behind a clean and pristine surface.

How does laser cleaning work?

Laser cleaning works by focusing a high-intensity laser beam onto the surface of the material to be cleaned. The energy from the laser beam interacts with the contaminants or coatings on the surface, causing them to either vaporize or ablate. This process is highly precise and does not damage the underlying material, making it ideal for delicate or sensitive surfaces.

Benefits of laser cleaning technology

- Non-contact cleaning method

- Environmentally friendly – no chemicals or abrasives needed

- Highly precise and selective

- Fast and efficient cleaning process

- Can be used on a wide range of materials

Applications of laser cleaning technology

- Industrial cleaning – removing rust, paint, and coatings from metal surfaces

- Historical restoration – cleaning delicate artifacts and monuments

- Electronics manufacturing – removing residues from circuit boards

- Medical device cleaning – sterilizing and cleaning medical instruments

Conclusion

Laser cleaning technology is a versatile and efficient method for removing contaminants and coatings from surfaces. Its non-contact and environmentally friendly nature make it a preferred choice for a wide range of applications.

#laser cleaning, technology, contaminants, coatings, rust, surface, laser beam, vaporize, ablate, precise, sensitive, non-contact, environmentally friendly, industrial cleaning, historical restoration, electronics manufacturing, medical device cleaning

długiego ogona: laser cleaning technology benefits, laser cleaning technology applications, laser cleaning technology process, laser cleaning technology advantages, laser cleaning technology uses, laser cleaning technology equipment, laser cleaning technology market, laser cleaning technology future trends, laser cleaning technology industry.

Advantages of laser cleaning over traditional cleaning methods

Advantages of Laser Cleaning over Traditional Cleaning Methods

Laser cleaning is a revolutionary technology that offers numerous benefits over traditional cleaning methods. From removing rust and paint to cleaning delicate surfaces, laser cleaning has proven to be more efficient, precise, and environmentally friendly. In this article, we will explore the advantages of laser cleaning and why it is becoming the preferred choice for many industries.

1. Precision

Laser cleaning allows for precise control over the cleaning process, ensuring that only the targeted area is treated. This level of precision is unmatched by traditional methods, which often result in damage to surrounding surfaces.

2. Efficiency

With laser cleaning, there is no need for chemicals or abrasive materials, making it a faster and more efficient cleaning method. The laser beam can quickly remove contaminants without leaving any residue behind.

3. Safety

Unlike traditional cleaning methods that may involve hazardous chemicals or abrasive materials, laser cleaning is a safe and environmentally friendly option. There is no risk of exposure to harmful substances, making it a safer choice for both workers and the environment.

4. Versatility

Laser cleaning can be used on a wide range of surfaces, including metal, plastic, glass, and even delicate materials like historical artifacts. This versatility makes it a valuable tool for various industries, from automotive to aerospace.

5. Cost-Effectiveness

While the initial investment in laser cleaning equipment may be higher than traditional cleaning methods, the long-term cost savings are significant. With reduced maintenance and downtime, laser cleaning can ultimately save businesses money in the long run.

6. Environmental Benefits

By eliminating the need for chemicals and abrasive materials, laser cleaning reduces the environmental impact of cleaning processes. It is a sustainable and eco-friendly option that aligns with modern environmental standards.

7. Quality of Cleaning

Laser cleaning provides a superior level of cleaning compared to traditional methods. The precision and efficiency of laser technology result in a cleaner surface with no damage or residue left behind.

In conclusion, laser cleaning offers numerous advantages over traditional cleaning methods, including precision, efficiency, safety, versatility, cost-effectiveness, environmental benefits, and quality of cleaning. As industries continue to adopt this innovative technology, the benefits of laser cleaning will become even more apparent.

#laser #cleaning #advantages #precision #efficiency #safety #versatility #costeffectiveness #environmentalbenefits #qualityofcleaning

frazy kluczowe:

– benefits of laser cleaning

– advantages of laser technology

– laser cleaning applications

– laser cleaning equipment

– laser cleaning process

– laser cleaning industry trends

– laser cleaning market growth

– laser cleaning vs traditional methods

– laser cleaning benefits for businesses

– laser cleaning impact on environment

Comparison of different laser cleaning systems for ceramics

Comparison of different laser cleaning systems for ceramics

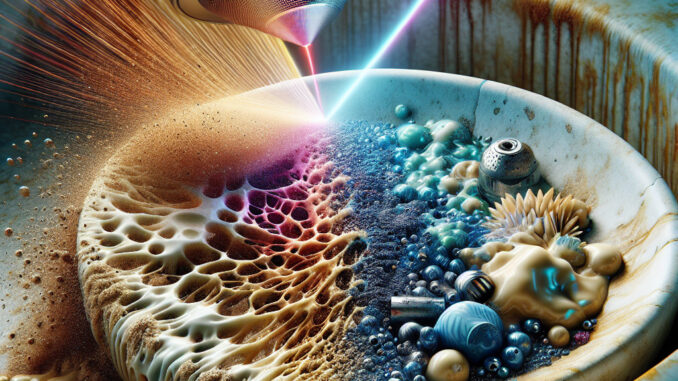

Ceramics are widely used in various industries due to their durability and resistance to high temperatures. However, over time, ceramics can accumulate dirt, grime, and other contaminants that can affect their performance. Traditional cleaning methods such as scrubbing or chemical cleaning may not be effective or efficient for delicate ceramic surfaces. Laser cleaning systems offer a non-contact and precise solution for cleaning ceramics without damaging the material.

Types of laser cleaning systems

There are several types of laser cleaning systems available on the market, each with its own advantages and limitations. The most common types include:

- Q-switched lasers: These lasers produce short pulses of high-energy light that can remove contaminants from ceramic surfaces without heating or damaging the material.

- Fiber lasers: Fiber lasers are highly efficient and can be used for precise cleaning of ceramics with minimal heat generation.

- CO2 lasers: CO2 lasers are suitable for removing organic contaminants from ceramic surfaces without damaging the material.

Comparison of laser cleaning systems

When choosing a laser cleaning system for ceramics, it is important to consider factors such as power output, wavelength, pulse duration, and spot size. Q-switched lasers are ideal for removing surface contaminants from ceramics, while fiber lasers are more suitable for precision cleaning of delicate surfaces. CO2 lasers are effective for removing organic contaminants but may not be as efficient for other types of contaminants.

Conclusion

In conclusion, laser cleaning systems offer a non-contact and precise solution for cleaning ceramics without damaging the material. Q-switched lasers, fiber lasers, and CO2 lasers are all effective for removing contaminants from ceramic surfaces, but each has its own advantages and limitations. It is important to choose the right laser cleaning system based on the specific requirements of the ceramic surface to be cleaned.

#laser cleaning, ceramics, Q-switched lasers, fiber lasers, CO2 lasers

#non-contact cleaning, precise cleaning, surface contaminants, organic contaminants, delicate surfaces, high-energy light, minimal heat generation, efficient cleaning, laser cleaning systems.

Laser parameters optimization for efficient cleaning of ceramics

Laser parameters optimization for efficient cleaning of ceramics

Ceramics are widely used in various industries due to their excellent mechanical and thermal properties. However, over time, ceramics can accumulate dirt, dust, and other contaminants, which can affect their performance and aesthetics. Traditional cleaning methods such as chemical cleaning or abrasive blasting may not be suitable for delicate ceramic surfaces. Laser cleaning offers a non-contact and environmentally friendly solution for removing contaminants from ceramics.

When it comes to laser cleaning of ceramics, optimizing laser parameters is crucial for achieving efficient and effective cleaning results. The key laser parameters that need to be optimized include:

- Laser wavelength: The wavelength of the laser beam determines its interaction with the ceramic surface. Different wavelengths are absorbed differently by ceramics, so selecting the right wavelength is essential for efficient cleaning.

- Laser power: The power of the laser beam affects the intensity of the cleaning process. Too low power may not be effective, while too high power can damage the ceramic surface. Finding the optimal power level is important for achieving the desired cleaning results.

- Laser pulse duration: The duration of the laser pulse also plays a role in the cleaning process. Shorter pulse durations are more suitable for delicate ceramics, while longer pulse durations may be needed for more stubborn contaminants.

- Laser spot size: The size of the laser spot determines the area that is being cleaned. Adjusting the spot size can help optimize the cleaning process for different ceramic surfaces.

By carefully optimizing these laser parameters, it is possible to achieve efficient and precise cleaning of ceramics without causing damage to the surface. Laser cleaning offers several advantages over traditional cleaning methods, including:

- Non-contact cleaning: Laser cleaning does not require physical contact with the ceramic surface, reducing the risk of damage.

- Environmentally friendly: Laser cleaning does not involve the use of chemicals or abrasive materials, making it a more sustainable cleaning solution.

- Precision cleaning: Laser cleaning can be controlled with high precision, allowing for selective removal of contaminants without affecting the underlying ceramic material.

In conclusion, optimizing laser parameters is essential for achieving efficient cleaning of ceramics. By carefully adjusting the laser wavelength, power, pulse duration, and spot size, it is possible to achieve precise and effective cleaning results. Laser cleaning offers a non-contact, environmentally friendly, and precise cleaning solution for ceramics in various industries.

Hashtags: #ceramics #laser #cleaning #optimization

Keywords: ceramics, laser cleaning, optimization, efficiency

Long-tail phrases: laser parameters optimization for efficient cleaning of ceramics, non-contact and environmentally friendly solution for removing contaminants from ceramics

Comparison of laser cleaning with other surface treatment methods for ceramics

One of the surface treatment methods that has gained popularity in recent years is laser cleaning. Laser cleaning is a non-contact, environmentally friendly, and precise method that uses a high-energy laser beam to remove contaminants or coatings from the surface of ceramics. Compared to traditional methods such as chemical cleaning or mechanical abrasion, laser cleaning offers several advantages including:

– Non-contact: Laser cleaning does not require physical contact with the surface of ceramics, which reduces the risk of damage or contamination.

– Precision: Laser cleaning can be controlled with high precision, allowing for selective removal of contaminants without affecting the underlying material.

– Environmentally friendly: Laser cleaning does not use chemicals or produce waste, making it a more sustainable option.

However, laser cleaning also has some limitations compared to other surface treatment methods. For example, laser cleaning may not be suitable for removing thick or stubborn contaminants, and it can be more expensive than traditional methods. Additionally, laser cleaning requires specialized equipment and trained operators, which can increase the overall cost of the process.

In comparison, other surface treatment methods such as chemical cleaning, mechanical abrasion, or plasma treatment also have their own advantages and disadvantages. Chemical cleaning is effective for removing organic contaminants, but it can be harmful to the environment and require proper disposal of chemicals. Mechanical abrasion is a cost-effective method for removing thick coatings, but it can damage the surface of ceramics. Plasma treatment is a versatile method that can modify the surface properties of ceramics, but it may require vacuum conditions and specialized equipment.

In conclusion, the choice of surface treatment method for ceramics depends on the specific requirements of the application, the type of contaminants or coatings to be removed, and the desired surface properties. Laser cleaning offers a non-contact, precise, and environmentally friendly option for cleaning ceramics, but it may not be suitable for all applications. Other surface treatment methods such as chemical cleaning, mechanical abrasion, or plasma treatment can also be effective depending on the specific needs of the project.

#ceramics #surface treatment #laser cleaning #chemical cleaning #mechanical abrasion #plasma treatment

#non-contact method #environmentally friendly #precision cleaning #surface modification #cost-effective method

Laser cleaning for removing rust and corrosion from ceramics

Laser cleaning for removing rust and corrosion from ceramics

Ceramics are a popular material used in various industries due to their durability and resistance to high temperatures. However, over time, ceramics can develop rust and corrosion, which can affect their performance and appearance. Traditional methods of removing rust and corrosion from ceramics, such as abrasive blasting or chemical treatments, can be time-consuming and may damage the surface of the material. Laser cleaning offers a precise and efficient solution for removing rust and corrosion from ceramics without causing any damage.

Laser cleaning works by using a high-powered laser beam to vaporize the rust and corrosion from the surface of the ceramic material. The laser beam is directed at the affected area, where it heats and evaporates the rust and corrosion, leaving behind a clean and smooth surface. Laser cleaning is a non-contact process, which means that there is no physical contact between the laser and the ceramic material, reducing the risk of damage.

One of the key advantages of laser cleaning is its precision. The laser beam can be controlled to target only the rust and corrosion, leaving the rest of the ceramic material untouched. This precision allows for selective cleaning of specific areas, making it ideal for intricate ceramic components with complex shapes.

Laser cleaning is also environmentally friendly, as it does not require the use of harsh chemicals or abrasive materials. This makes it a safer and more sustainable option for removing rust and corrosion from ceramics. Additionally, laser cleaning is a fast process, with most jobs being completed in a matter of minutes, saving time and reducing downtime.

In conclusion, laser cleaning is a highly effective and efficient method for removing rust and corrosion from ceramics. Its precision, speed, and environmental friendliness make it a superior alternative to traditional cleaning methods. By using laser cleaning, industries can prolong the lifespan of their ceramic components and maintain their performance and appearance.

- precision

- efficiency

- environmentally friendly

- non-contact

- selective cleaning

- removing rust and corrosion from ceramics

- laser cleaning for ceramics

- efficient rust removal

- environmentally friendly cleaning

- precision cleaning method

#rustremoval #ceramics #laser #cleaning #precision #efficiency #environmentallyfriendly #noncontact #selectivecleaning #rustandcorrosionremoval

Laser cleaning for removing grease and oil from ceramics

Ceramics are widely used in various industries due to their durability and resistance to high temperatures. However, one of the challenges in maintaining ceramics is the accumulation of grease and oil on their surfaces. Traditional cleaning methods such as scrubbing or chemical solvents may not be effective in removing stubborn grease and oil stains. Laser cleaning has emerged as a powerful and efficient solution for removing grease and oil from ceramics.

How does laser cleaning work?

Laser cleaning uses a high-energy laser beam to vaporize contaminants on the surface of ceramics. The laser beam is focused on the grease and oil stains, causing them to evaporate without damaging the ceramic surface. This process is non-contact and non-abrasive, making it ideal for delicate ceramics.

Benefits of laser cleaning for ceramics

- Efficient removal of grease and oil stains 🔥

- Non-contact and non-abrasive process 💫

- No chemicals or solvents required 🌿

- Precision cleaning without damaging the ceramic surface 🎯

Applications of laser cleaning in ceramics industry

Laser cleaning is widely used in the ceramics industry for removing grease and oil from various products such as tiles, kitchenware, and industrial components. It is also used for restoring antique ceramics without causing any damage to their delicate surfaces.

Conclusion

Laser cleaning is a highly effective and efficient method for removing grease and oil from ceramics. Its non-contact and non-abrasive nature make it ideal for delicate ceramics, ensuring precision cleaning without any damage to the surface. With the increasing demand for clean and pristine ceramics, laser cleaning is becoming a popular choice for industries looking to maintain the quality of their products.

#laser #cleaning #ceramics #grease #oil #removal

Keywords: laser cleaning, ceramics, grease, oil, removal

Long-tail phrases: laser cleaning for ceramics, efficient removal of grease and oil stains, non-contact and non-abrasive cleaning method

Laser cleaning for removing stains from ceramics

Ceramics are a popular choice for kitchenware, bathroom tiles, and decorative items due to their durability and aesthetic appeal. However, over time, ceramics can become stained and discolored, detracting from their beauty. Traditional cleaning methods such as scrubbing with harsh chemicals can damage the surface of the ceramics and may not effectively remove tough stains.

Laser cleaning offers a safe and efficient solution for removing stains from ceramics without causing any damage to the surface. This innovative technology uses a high-powered laser beam to vaporize contaminants on the surface of the ceramics, leaving them clean and pristine.

Here are some benefits of using :

- Non-contact cleaning method: Laser cleaning does not require any physical contact with the ceramics, reducing the risk of scratching or damaging the surface.

- Environmentally friendly: Laser cleaning does not involve the use of harsh chemicals, making it a safe and eco-friendly cleaning option.

- Precision cleaning: Laser technology allows for precise control over the cleaning process, ensuring that only the stained areas are targeted.

- Efficient and time-saving: Laser cleaning is a fast and efficient cleaning method, saving time and labor compared to traditional cleaning methods.

Overall, laser cleaning is a highly effective and safe method for removing stains from ceramics, restoring them to their original beauty without causing any damage. Whether you have stained kitchenware, bathroom tiles, or decorative ceramics, laser cleaning can help you achieve a clean and pristine finish.

Hashtags: #laser #cleaning #ceramics #stains

Keywords: laser cleaning, ceramics, stains, non-contact cleaning, environmentally friendly

Long-tail phrases: innovative technology for cleaning ceramics, safe and efficient stain removal, precision cleaning with laser technology